To control microbiological growth, scale formation and metal corrosion, water in cooling towers must be treated. Three processes take place in the Industrial Vortex Generator: the crystallization of minerals, the removal of unbound gas such as micro bubbles, and fighting microbial growth by damaging the cell wall. Soluble forms of calcium (such as calcium (bi)carbonate) are converted to calcite and aragonite. The cavitation forces produce crystals that do not adhere to pipes, nozzles, heat exchangers or other surfaces. IVG reduces viscosity by 12-20% and improves heat transfer by 3-5% for optimal cooling.

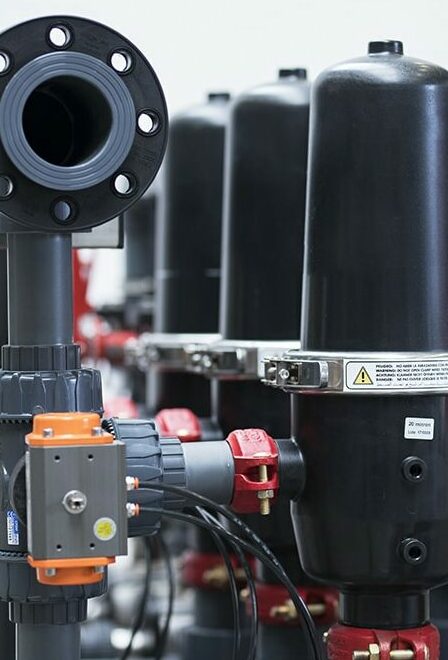

Spinning Disk Filtration continuously filters the cooling water is in a recirculation loop with a flow rate of 40-50 m3/hour. The SDF filters the water with fast rotating movements to keep the suspended particles in the cooling water as low as possible. This improves the capacity of the UV-C reactor and reduces the chance of microbiological growth. SDF removes abrasive particles from the water for a longer service life of materials and pumps, and prevents sedimentation and blockages in pipes and heat exchangers.

Where water is used, biofilm can form. Fungi, yeasts and bacteria that live in biofilms pose a health and safety hazard. UV-C is invisible radiation with a wavelength between 100 and 280 nm. Rays of this wavelength damage the DNA of microorganisms. The UV-C light neutralizes the micro-organisms and prevents them from reproducing.

In large cooling water systems, it is necessary to introduce a disinfectant to the water, in addition to the IVG and UV-C. The PaDes system (PAthema DESinfect) disinfects water by electrolyzing it without adding chemicals. The treated water contains free chlorine produced from the chloride already present in the cooling water or in the form of table salt. This way we keep the pipes, exchangers and the cooling water basin free of contamination such as bacteria or biofilm. Salt electrolysis is based on the conversion of dissolved salt into temporary chlorine by means of a low voltage direct current. After the free chlorine has done its disinfecting work, it is converted back into dissolved chloride and oxygen.